|

Utjecaj deformacija od puzanja

na nosivost čeličnih i aluminijskih stupova

pri djelovanju požara

|

Project Summary

High temperature creep represents one of the important factors influencing the response of steel and aluminium structures during fire exposure. Influence of creep is mostly observed through additional increase of displacements in case of statically determinate structural systems and through the increase of the internal forces in case of statically indeterminate systems. In both cases the creep of steel and aluminium at high temperature reduces the load capacity of a member or a part of a structure. Furthermore, the behaviour of steel and aluminium columns under the influence of high temperature creep is currently an open research area in the scientific community, since very few fire tests have been conducted on steel columns which could induce substantial creep development and the corresponding failure modes. Additional motivation for investigating the influence of creep is the fact that the modern European structural codes (Eurocode) treat existence of creep strain implicitly, using a modified material behaviour model, which has proven inadequate for all of possible heating scenarios.

The purpose of the project is to develop new types of creep models applicable to new types of steel and aluminium alloys and to conduct the analysis of the influence of creep strain on the behaviour of steel and aluminium columns during fire exposure, which represent the most sensitive parts of the whole structure during collapse stage. The initial stage of the project covers conducting tests for determining stationary creep curves. The curves would be obtained on different temperature and stress levels with the purpose of creating new types of analytical/rheological creep models. The developed creep models are intended to be implemented into two research codes developed by the PI's host institution and by the institution of the external member of the project team. The codes will subsequently be used for numerical modelling of the behaviour of steel and aluminium columns influenced by creep. Following the implementation of the creep models, fire tests which cover testing of steel and aluminium columns exposed to different load and temperature levels are planned, including transient heating curves, which would induce significant development of creep strain in the columns. In the final stage of the project verification of the developed creep models is planned using columns’ fire test results. A new insight into the behaviour of steel and aluminium columns under creep influence would be obtained including the insight into types of fire heating scenarios causing a significant increase of creep strain. Conclusions obtained on the basis of the performed tests would be suitable for creating new set of design rules for steel and aluminium structures in fire.

Project team

Team members:

- Assistant professor Neno Torić

- Professor Ian Burgess (University of Sheffield)

- Professor Alen Harapin

- Professor Ivica Boko

- Associate professor Mirela Galić

- Assistant professor Vladimir Divić

- Ivana Uzelac, PhD

- Marko Goreta, MEng

- Jelena Lovrić Vranković, MEng

Assistant professor Neno Torić, principal investigator, is an expert in the field of analysis of the behaviour of steel and concrete structures exposed to fire. His field of expertise includes development of new types of numerical models for behaviour of structures exposed to fire and development of corresponding experimental tests.

Prof. Ian Burgess is a leading expert in developing new numerical techniques for modelling of the behaviour of steel and composite elements in fire. He is also a leader of a fire research group which is part of the University of Sheffield. The main thrust of the research remains in numerical modelling, but some very successful experimental work has been done at Sheffield in developing a component approach to connection modelling for fire conditions. So far the research programme on fire has 28 PhD and 3 MPhil graduates and has generated more than 250 publications.

Project goals

The scientific goals within the framework of the proposed project can be divided into two parts. The first part is the development of a reliable creep model for steel and aluminium that will exist both in an analytical form and in the form of a rheological model. A creep model validated on the basis of coupon tests conducted on the modern steel and aluminium alloys currently used in construction would be used as a tool for analyzing the load-bearing capacity of the columns selected for testing within the proposed project. Furthermore, the development of a creep model with a rheological background would create a more flexible solution to the problem and be applicable in conducting a wide spectrum of creep analyses at high temperature, which would not be possible when the previously developed semi-empirical or empirical creep models are used.

The second part of the goal is to conduct successful testing of steel and aluminium columns which would provide a verification of previously developed creep models. The developed creep models would in turn be used in quantifying the influence of creep strain on the reduction of the load-bearing capacity of columns. The second part would also give a reliable answer to the question of the significance of the influence of creep strain on the load-bearing capacity, as well as elucidating the issue of particular combinations of loading and heating scenarios in which creep strain leads to significant consequences.

The final results and conclusions covering the project’s deliverables would be utilized to define a new set of rules for the design and analysis of steel and aluminium structures which have a high risk of being exposed to the effects of creep strain, when exposed to fire. This kind of design approach is not taken into account in current civil engineering codes valid in the Republic of Croatia. By analyzing previous research results, it can be concluded that a suitable design approach taking creep into account is necessary for the design of steel and aluminium structures.

Activities

- Analysis of the existing creep models and selection of a certain type of steel and aluminium alloy on which further research will be conducted

- Completion of tests for determining creep properties of steel and aluminium coupons and precondition for starting development of analytical and rheological creep model

- Development of rheological models for primary and secondary creep phase of steel and aluminium at high temperature by using the parameters obtained from the analysis of coupon test results

- Programming the developed rheological/analytical creep models into selected research codes and interfacing them into the FEM analysis procedure

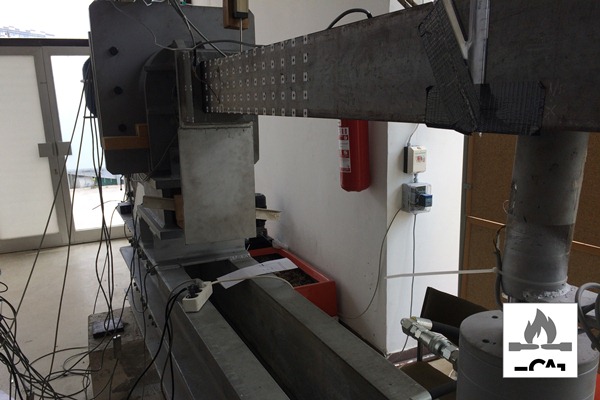

- Installation of a Laboratory for testing of structural members exposed to high temperature

- Experimental tests on steel columns by applying stationary test method at different temperature levels (100-800°C) and by applying transient testing method (using load levels from 20%-80% of the columns' axial load capacity at atmospheric temperature)

- Experimental tests on aluminium columns by applying stationary test method at different temperature levels (100-500°C) and by applying transient testing method (using load levels from 20%-80% of the columns' axial load capacity at atmospheric temperature)

- Verification of the implemented rheological/analytical creep models for steel at high temperature

- Verification of the implemented rheological/analytical creep models for aluminium at high temperature

Publications

A unified rheological model for modelling steel behaviour in fire conditions. Torić N., Burgess I. W. Journal of Constructional Steel Research, Vol. 127 (2016), pages 221–230.

A Unified Rhelogical Model for Analysis of Steel Behaviour at High Temperature. Torić N., Burgess I. W., Brnić J., Boko I., Turkalj G., Čanadija M., Harapin A., Divić V., Uzelac I. Structures in Fire 2016, Proceedings of the Ninth International Conference, pages 1008-1015, Princeton, USA.

Creep Properties of Grade S275JR Steel at High Temperature. Torić N., Brnić J., Boko I., Čanadija M., Turkalj G., Lanc D., Brčić M., Burgess I. W., Harapin A., Divić V., Uzelac I. EUROSTEEL 2017, September 13–15, 2017, Copenhagen, Denmark.

High-temperature Properties of Aluminium Alloy EN6082AW T6. Torić N., Brnić J., Boko I., Čanađija M., Turkalj G., Lanc D., Brčić M., Uzelac I., Burgess I.W., Harapin A., Divić V., Galić M. ASFE 2017, Applications of Structural Fire Engineering, September 7-8, 2017, Manchester, United Kingdom.

Sustainibility of Aluminium in Construction Practice - Recent Fire Related Research. Torić N., Glavinić Uzelac I., Boko I. 1st International Conference on Construction Materials for Sustainable Future, Book of Abstracts of the 1st International Conference CoMS_2017, April 19-21, 2017, Zadar, Croatia.

Experimental Analysis of the Behaviour of Aluminium Alloy EN6082AW T6 at High Temperature. Torić N., Brnić J., Boko I., Brčić M., Burgess I. W., Uzelac I. Metals 7 (4). 126. ISSN 2075-4701.

Development of a high temperature material model for grade s275jr steel. Torić N., Brnić J., Boko I., Brčić M., Burgess I. W., Uzelac Glavinić I. Journal of Constructional Steel Research, Vol. 137 (2017), pages 161-168.

Torić, N., Uzelac Glavinić, I., Burgess, I. W., Development of a rheological model for creep strain evolution in steel and aluminium at high temperature, Fire and Materials, 2018. (DOI:10.1002/fam.2643)

Goreta, M., Torić, N., Divić, V., Boko, I., Lovrić Vranković J., Testing the influence of creep on fire-exposed aluminium columns, Proceedings of 9th International Congress of Croatian Society of Mechanics, 2018, Split, Croatia.

Torić, N., Boko, I., Divić, V., Burgess, I., Goreta, M., Experimental analysis of the influence of creep of fire-exposed steel and aluminium columns, Structures in Fire 2018, Proceedings of the 10th International Conference, pages 619-624, Belfast, UK.

Torić, N., Boko I., Divić, V., Burgess, Ian W., Behaviour of Steel Grade S275JR Columns under the Influence of High-Temperature Creep, Metals (2018): Vol. 8 (11), 874. (DOI:10.3390/met8110874)

News

Since February 2017 intensive testing on the load capacity of steel columns at ambient temperature has been carried out. Conducted tests include strain and displacement measurements by using LVDT units and tape measurement, combined with photogrammetric measurements of displacement when the column is exposed to external load.

Photo Video Gallery

23.05.2018. Final project meeting at the Faculty of civil engineering, architecture and geodesy.

21.05.2018. Professor Ian Burgess from The University of Sheffield visited University of Split, and held a lecture at the Faculty of civil engineering, architecture and geodesy. The topic of the presentation: THE DUCTILITY DEMAND OF STEEL-FRAMED STRUCTURES IN FIRE.

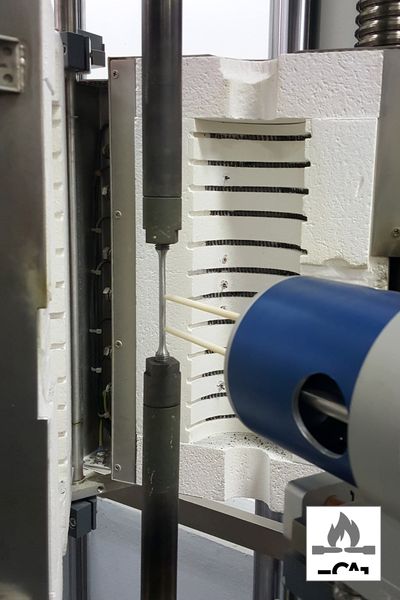

17.11.2017. Short video of the high-temperature column test.

This short video presents high-temperature column test comprised of two stage: heating stage where column is heated at prescribed temperature level and loading stage where column is subjected to external load.

01.09.2017. High temperature tests on steel columns. High temperature column tests have started since the middle of August.

22.05.2017. Professor Ian Burgess from The University of Sheffield visited University of Split, and held a lecture at the Faculty of civil engineering, architecture and geodesy.

21.04.2017. 1st International Conference on Construction Materials for Sustainable Future in Zadar.

14.04.2017. Preliminary tests on the load capacity of steel columns at ambient temperature.

30.09.2016. Setup of the testing unit for steel and aluminum columns at Faculty of civil engineering, architecture and geodesy.

16.05.2016. Meeting at the Faculty of civil engineering, architecture and geodesy. Professor Ian Burgess from The University of Sheffield has arrived at University of Split.

Coupon tests at University of Rijeka, Faculty of Engineering

Coupon tested at 20°C

Steel columns for testing

Aluminium columns for testing